Roll crusher with teeth DVZ-2/800

Roll crusher with teeth DVZ-2/800 is intended for crushing lump materials of low and medium strength. The crusher can be used in production lines and crushing complexes, as the first or second stage of crushing large pieces of materials.

The use of this crusher for grinding difficult, radioactive and explosive materials is not recommended.

The crusher can be used both as a stand-alone machine and as part of a plant or a production line.

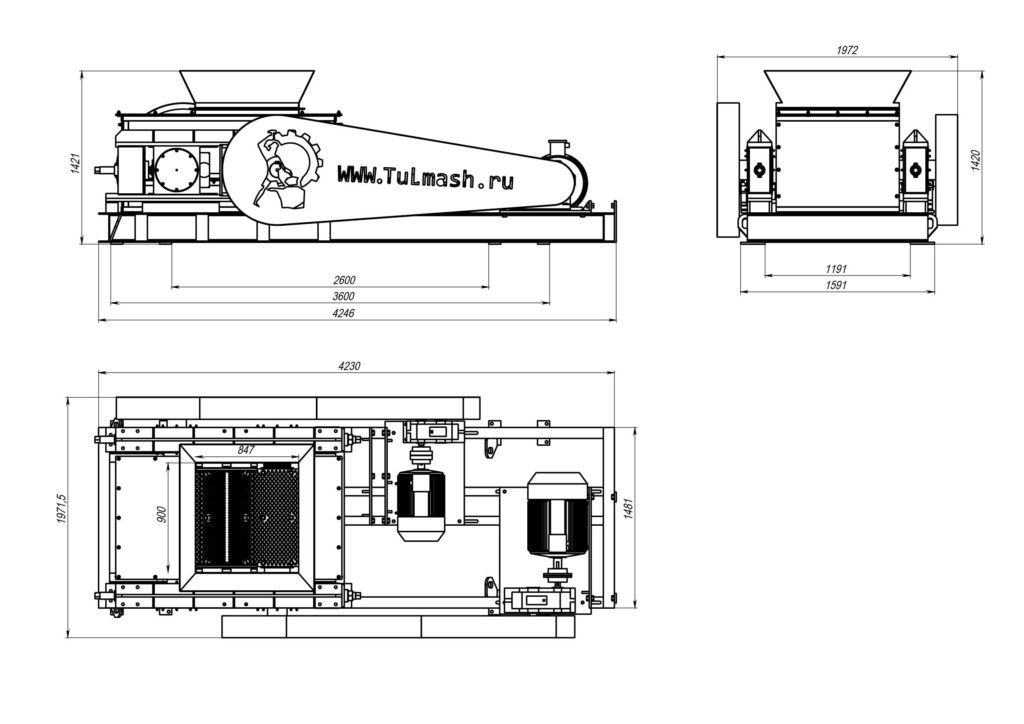

Dimensional and connecting drawing of the DVZ-2/800 roll crusher

The crusher can be installed on supporting platforms, legs or metal constructions of foundations.

DVZ-2/800: Technical data

| Parameters | Values |

| Design capacity, m3/h | Up to 350* |

|

Rotors RPM |

115/160 |

|

Rotor diameter, mm |

800 |

|

Active rotor length, mm |

800 |

| Electric motors: | |

| — type | AIR225М4UZ; 4А180М4UZ |

| — power, kW |

30; 55 |

|

— rpm |

1.500; 1.500 |

| — voltage, V |

380 |

| Speed reducer 1 | 1TZU-160-3.15-12-TZ-TZ-2-2U |

| Speed reducer 2 | 1TZU-200-3.15-12-TZ-TZ-2-2U |

|

Belt drives |

2.85; 4 |

| Crusher weight (assembled), kg | ~7.700 ** |

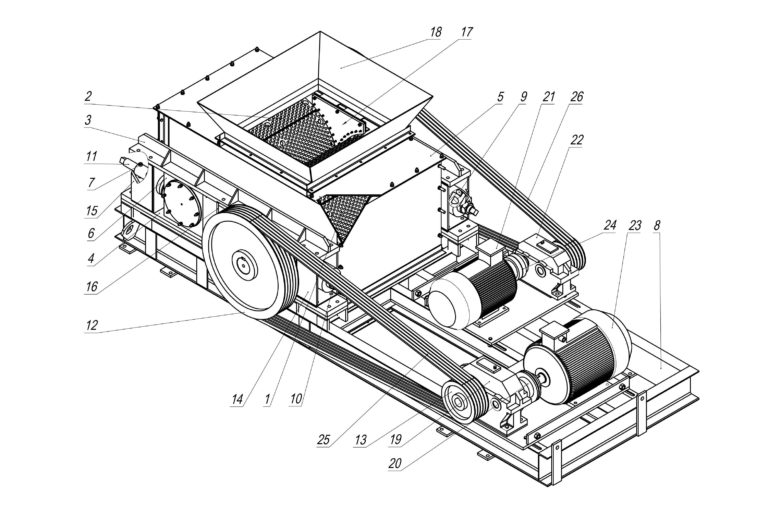

Device of roller crusher DVZ-2L

The crusher has a welded frame 8, on which a casing 5 is mounted with a stationary positioned rotor 2 and a free positioned rotor 1, installed in bearing cases 6. The bearing cases are mounted between rails 3 and 4 in which there are special grooves for guides, moving the rotor 1 along which allows to adjust the gap between the rotors (and to release hard objects jammed between the rotors). The gap between the rotors is adjusted by moving the bearing cases 6 with the rotor 2 using adjusting screws 11. The cases 6 are moved along two pairs of guides: lower and upper. The rotors are fixed using two nuts 7.

The free positioned rotor is driven by an electric motor 23 using a belt drive 28, speed reducer 19 and a coupler 20.

The stationary positioned rotor is driven by an electric motor 21 using a belt drive 27, a speed reducer 22 and a coupler 24.

The crusher has a loading hopper 18 for loading source materials.

In the lower part of the crusher there is an unloading hopper 17 for unloading crushed materials into a special container or on transporting systems. Belt drives are guarded by protective covers.

The crusher assembled is mounted on support legs.

Springs 9 with an adjustable compression ratio are intended to prevent damage to the crusher when hard objects get between the rotors. The compression ratio of the springs 9 is adjusted using screws 10.

The principle of operation of the DVZ 2/800 roll crusher

The principle of operation of the roll crusher is based on abrasion processes (simultaneous action of compression and shear forces) between the rotors rotating at different speeds towards each other.

During crusher operation, the source material is loaded into a loading hopper 18, where it freely falls on rotating rotors 1 and 2. Then material pieces are crushed between rotors. The crushed product is poured on unloading devices.

Different speeds of rotation of the rotors increase the efficiency of catching crushed material particles and capacity of the crusher. The final product particle size can be adjusted by the gap between the rotors.

When hard objects get between the rotors, the free positioned rotor 1 compresses its protective springs 9, and the objects fall into the unloading hopper, thus, crusher breakage is prevented. In some hard cases, rotors jamming still may occur.

The compression ratio of the springs 9 directly influences the capacity of the crusher: at low values of this parameter, hard particles can freely pass between the rotors, without being crushed.

The required compression ratio of the springs is chosen by results of experiments.

The special feature of the roll crusher is an opportunity to provide a specified final product particle size with a minimum degree of overgrinding. The maximum size of final product pieces is limited, first of all, by properties of a particular material and a gap between the rotors.