Roll crusher with fluted rotors DVR 2L

Roll crusher with fluted rotors DVR 2L is intended for crushing lump materials of low and medium strength (70-120 MPa, 700-1200 kgf/cm 2 ) with moisture content of up to 25%. It is used for fine and medium size crushing chalk, marl, coal, clay shale, as well as grinding (with simultaneous crushing) viscous and wet materials, such as clays.

Materials are caught by rotating towards each other rotors and crushed using compression and abrasion forces. One time compression in the working space of the crusher provides small yield of overcrushed materials. The roll crusher with fluted rotors ensures better rotor engagement with crushed materials due to fluted rotor surfaces.

The crusher can be installed both indoors and outdoors (using tents).

Roll crusher DVR 2L: Technical data *** |

||

| Parameters | Values * | |

| Design capacity, m 3 /h (gap between rotors: 10 mm) |

Up to 40* | |

| Source material particle size d н , mm (at minimum gap between rotors) |

0-40* |

|

|

Rotors RPM |

150/300 |

|

|

Rotor diameter, mm |

500 |

|

|

Active rotor length, mm |

820 |

|

|

Final product particle size, mm |

min: 0-1; max: 0-20 mm (95%) **** |

|

|

Motor power, kW |

18.5; 37* | |

|

Voltage, V |

380 |

|

|

Crusher weight, kg |

3.870 | |

* Parameters varied depending on physical properties of materials.

** Depends on requirements of customers. Final product particle size depends on a particular gap between the rotors.

*** All the values are calculated or taken on the basis of materials previously processed by this crusher.

**** The particle size can be increased by increasing the gap between the rotors.

Please find out current prices by phone +7-800-700-46-86.

The following auxiliary electrical equipment can be purchased additionally to your crusher: power switchboards, cable products, automation systems.

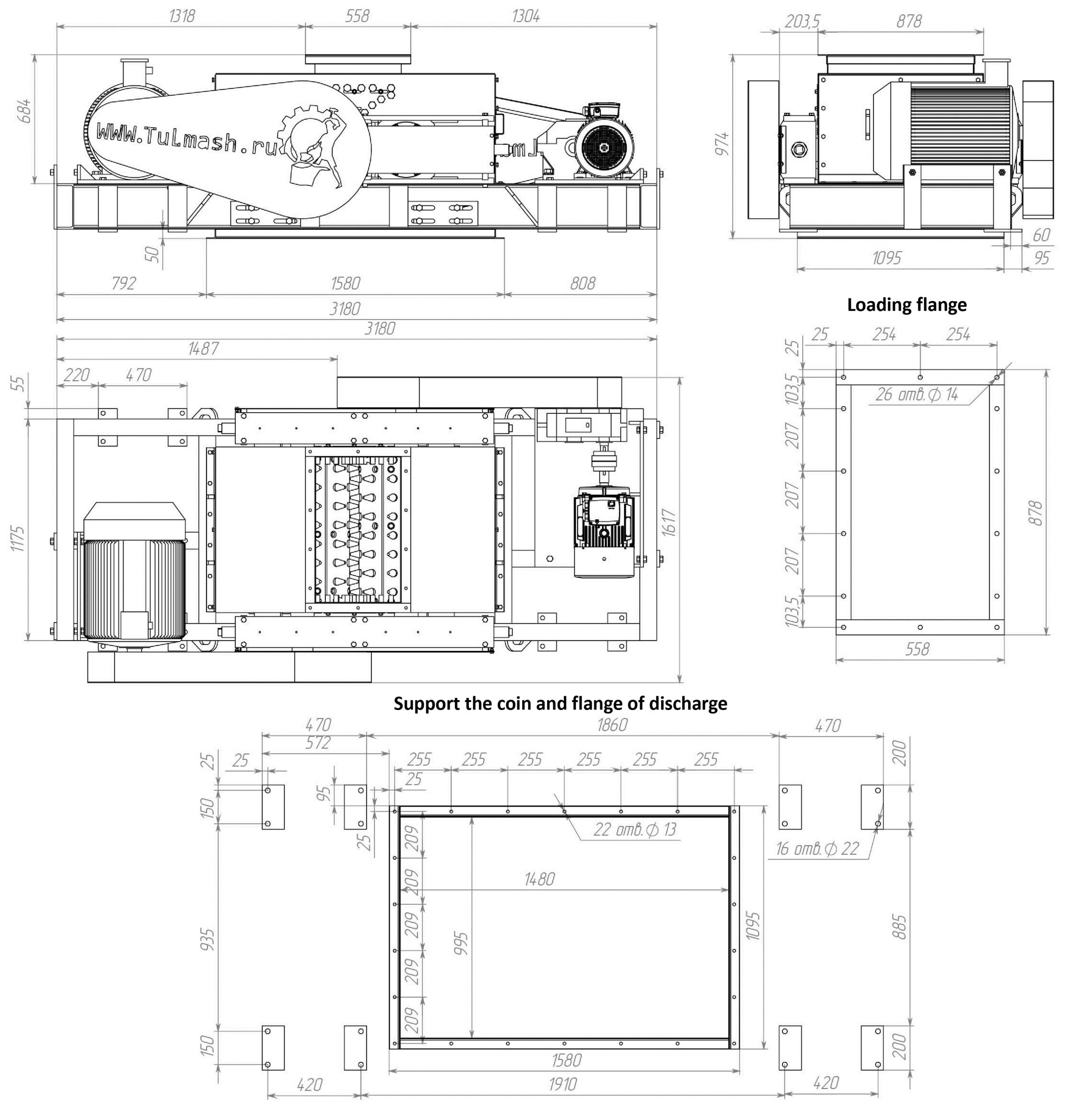

Dimensional and connecting drawing of the DVR 2L roll crusher

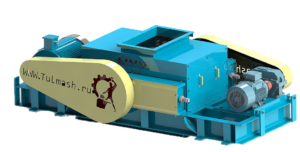

Pictures of DVR 2L Roller Crusher

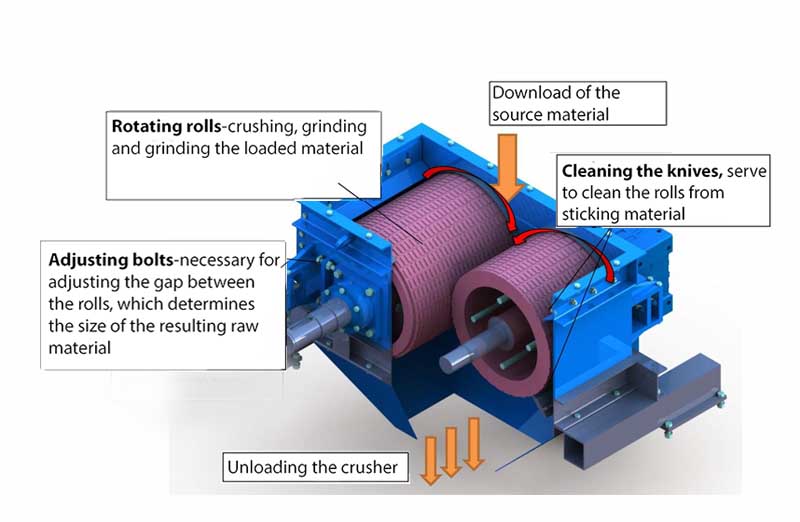

Device of roller crusher DVZ-2L

Main quick-wearing parts of the crusher: rotor pads (steel 70HL).

Main quick-wearing parts of the crusher: rotor pads (steel 70HL).