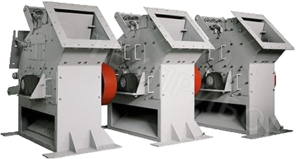

Rotor impact crusher SMD 10

The machine is intended for fine and medium particle size crushing metallurgical slag, limestone, dolomite, marl, marble, gypsum, law-abrasive ores and other similar materials, the strength of which does not exceed 600 kgf/cm2, with a source material particle size of no more than 350 mm.

Rotor impact crusher SMD 10: Technical data |

||

| Parameters | Value* | |

| Design capacity, t/h | 12* | |

| Source material particle size dн, mm | 380* | |

| Overall dimensions, mm: | 1.800×933×1.520 | |

| Weight, kg | 1,330 | |

| Installed power, kW | 11 | |

| Hammer linear velocity, m/s | 26 | |

| Length and diameter of the rotor with hammers, mm | 400/500 | |

| Loading window, mm | 430х420 | |

* Parameters varied depending on physical properties of materials.

Please find out current prices, discounts and special offers by phone 8-800-700-46-86.

The following auxiliary electrical equipment can be purchased additionally to your machine: power switchboards, cable products, automation systems.

The machine SMD 10 is classified as a rotor impact crusher. The processed material is crushed by hammers rigidly fixed on the rotor and also by corresponding breaker plates. Rotor impact crusher SMD 10 is characterized by high capacity and relatively low power consumption, it is easy to use and reliable. In addition, SMD 10 does not require a large supporting foundation.

More over, SMD 10 can be used as a dynamic granulator for processing rock materials. The materials are processed with crushing weak aggregates without weakening the structural strength of target products.

The design and operation of the rotor impact crusher SMD 10

In this case materials are crushed by dynamic processes, using hammers and breaker plates. SMD 10 is a crushing machine with three stages of kinetic crushing. At the first stage, the source material hits a rapidly rotating rotor with hammers, then stationary internal breaker plates, and at the third stage, the processed material crushed into small pieces is ground by the impact interaction of particles.

The working parts of SMD 10 are its massive rotor with rigidly fixed hammers and corresponding breaker plates.

Raw materials can be crushed into particles of specified sizes. To adjust the fractional composition of the final product, it is necessary to adjust the gap between rotor hammers and breaker plates. This is carried out using a special multipurpose spring device providing a specified crushing force. The final product is unloaded from the machine using an inclined guide.

«Tula Machines» produces rotor impact crushers SMD 10, taking into account customer requirements and in compliance with corresponding technical codes and rules. We guarantee high capacity, low power consumption and specified fractional compositions of cube-shaped final products.