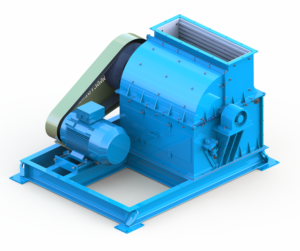

Hammer crusher MPS 950-B

Hammer crusher MPS 950-B is intended for grinding mineral and technological raw materials with low abrasiveness and a melting point of not less than 250 С, with moisture content at which the crusher grate is not jammed.

The use of this crusher for grinding radioactive and explosive materials, and also materials with medium and high abrasiveness is not recommended.

The crusher can be used both as a stand-alone machine and as part of a plant or a production line.

The crusher can be installed on supporting platforms, legs or metal constructions of foundations. The crusher can be installed both indoors and outdoors (under tents).

The design and principle of operation

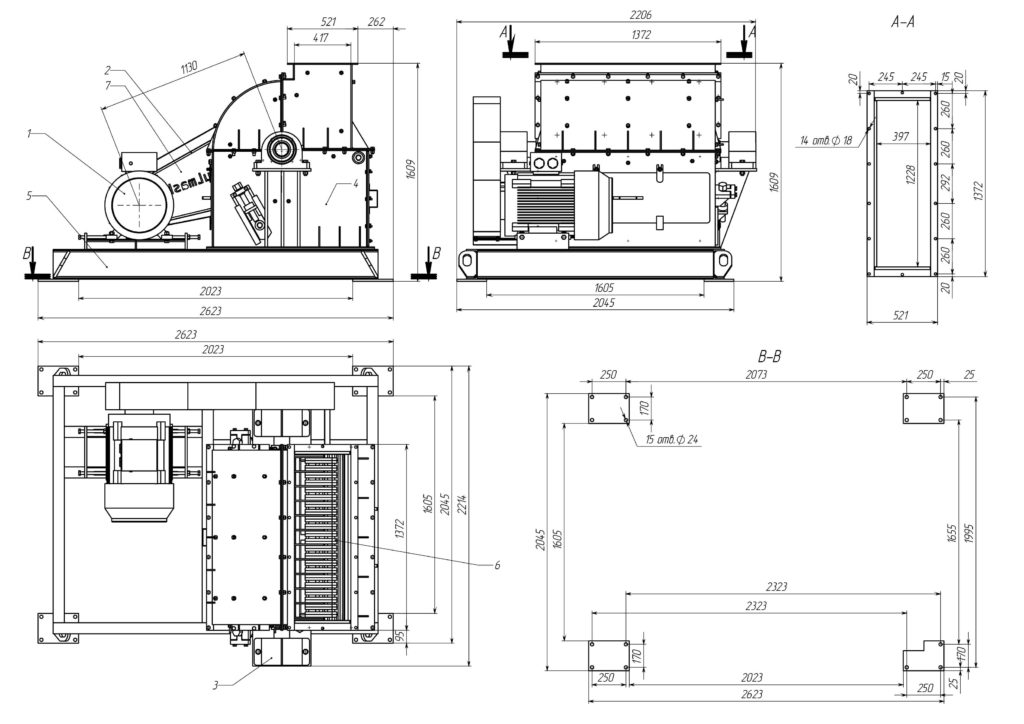

The crusher is driven from the electric motor (pos. 1) by means of the belt drive (pos. 2). The rotor (pos. 6) is mounted in bearing casings (pos. 3) installed at the crusher casing (pos. 4). The electric motor and the crusher casing are installed on the common frame (pos. 5). Outer rotating parts are guarded by the protective cover (pos. 7).

A source material is continuously fed through the crusher hopper. Crushing occurs as a result of the combined impact of hammers, breaker plates and grates. The final product is poured through holes in the grates and a special technological window. The gap between the grates and rotor hammers can be adjusted to compensate for the wear of hammers/grates.

During the operation of the crusher, the upper part of the loading hopper must be covered by a special device to prevent material ejection.

Hammer crusher MPS 950-B: Technical data *** |

||

| Parameters | Values | |

| Capacity, t/h | Up to 50* | |

| Rotor RPM | 1.100 | |

| Rotor diameter, mm | 900 | |

| Rotor length, mm | 1,218 | |

| Source material particle size dн, mm | 210 | |

| Final product particle size dк, mm | 0-5 ** | |

| Electric motor:

— power, kW — RPM |

75.0

1.500 |

|

| Crusher overall dimensions, mm — length— width— height |

2.623

2.214 1.609 |

|

| Crusher weight, kg | 3.740 | |

The information for design and engineering companies

For ease of use of our products in your projects, we provide a 3D-model of the machine, based on overall dimensions and mounting sizes. This service, presented on our website, will help designers to save their time.